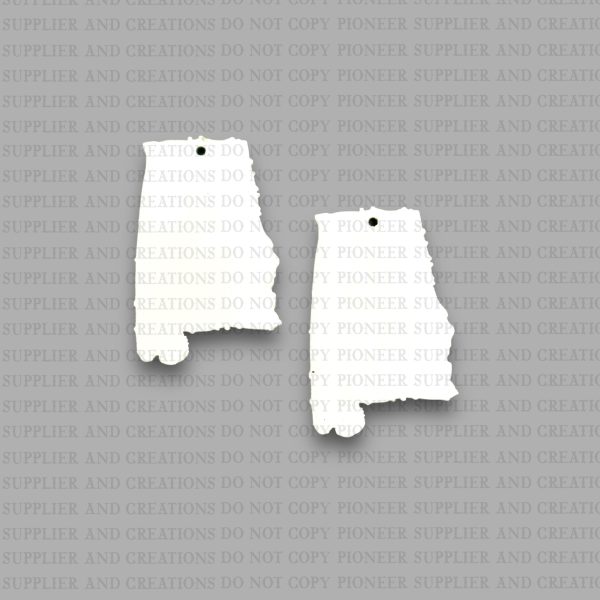

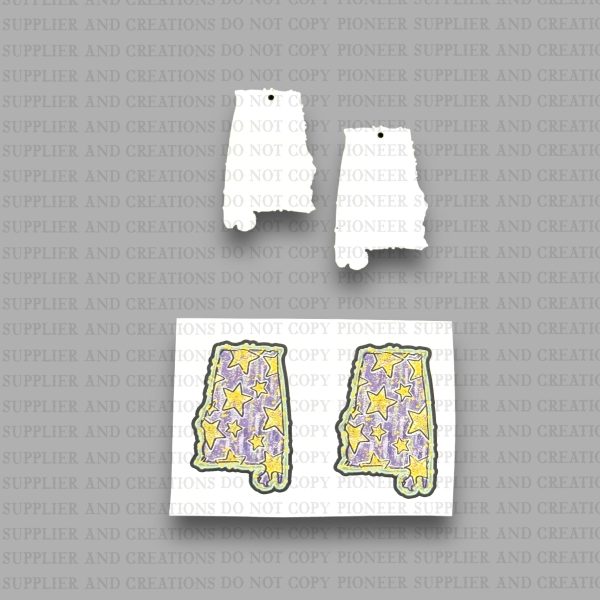

Alabama Mardi Stars Earring Sublimation Blanks | Exclusive Pixel Pop on Sale

Description

This unisub MDF sublimation blank was created solely for using with the image which can be found HERE

*DESIGN NOT INCLUDED* AND MUST BE PURCHASED SEPARATELY IF YOU DO NOT ORDER THE TRANSFER SET*

Please send Pioneer a message or email us (pioneersupplierandcreations@gmail.com) if you need help matching this design to our blank

Finished Size | W 1.11 H 1.7

Print Size | W 1.21 H 1.8 | Print Same Sides

MDF Unisub – approx. 2.8mm thick (MUST BE MIRRORED)

Acrylic Unisub – approx. 4.6mm thick (DO NOT MIRROR)

Click HERE to see all blanks for Pixel Pop

✔️ Sold as 1 pair (2 pcs) or in kits of 2 or 4 pair

✔️ Single sided

✔️ Gloss (clear film) Matte (blue film) Acrylic (clear film both sides)

✔️ IMAGE MUST BE PURCHASED SEPARATELY IF YOU DO NOT ORDER THE TRANSFER SET

✔️ PNG Template download emailed upon order fulfillment

✔️ Backside of single sided mdf blanks are unfinished and may have some burn marks around the edges due to the nature of being laser cut.

PRESSING INSTRUCTIONS for Unisub MDF:

- Remove all the clear or blue film from the substrate.

-

- Remove residue, if any, with a soft damp cloth from unisub MDF.

-

- Place your MDF substrate onto your transfer and secure with heat tape.

-

- Press for 50-55 seconds @ 380 degrees medium pressure. (Time and temp may vary based on your heat press

-

PRESSING INSTRUCTIONS for Unisub Acrylic:

- Remove the clear film from both sides of the substrate.

-

- Place your acrylic substrate onto your transfer and secure (white side against transfer). I use 3m repositional spray so I do not end up with tape indentions on acrylic.

-

- Press for 120 seconds @ 355 degrees medium pressure. (Time and temp may vary based on your heat press)

-

- Immediately remove and apply heavy even pressure on a smooth flat surface to cool so it will not warp. Make sure all surfaces are clean of grit (all will cause indents on substrate)

-

Please send Pioneer a message or email us (pioneersupplierandcreations@gmail.com) if you need help matching this design to our blank

Finished Size | W 1.11 H 1.7

Print Size | W 1.21 H 1.8 | Print Same Sides

MDF Unisub – approx. 2.8mm thick (MUST BE MIRRORED)

Acrylic Unisub – approx. 4.6mm thick (DO NOT MIRROR)

Click HERE to see all blanks for Pixel Pop

✔️ Sold as 1 pair (2 pcs) or in kits of 2 or 4 pair

✔️ Single sided

✔️ PNG Template download emailed upon order fulfillment

✔️ Backside of single sided mdf blanks are unfinished and may have some burn marks around the edges due to the nature of being laser cut.

PRESSING INSTRUCTIONS for Unisub MDF:

- Remove all the clear or blue film from the substrate.

-

- Remove residue, if any, with a soft damp cloth from unisub MDF.

-

- Place your MDF substrate onto your transfer and secure with heat tape.

-

- Press for 50-55 seconds @ 380 degrees medium pressure. (Time and temp may vary based on your heat press

-

PRESSING INSTRUCTIONS for Unisub Acrylic:

- Remove the clear film from both sides of the substrate.

-

- Place your acrylic substrate onto your transfer and secure (white side against transfer). I use 3m repositional spray so I do not end up with tape indentions on acrylic.

-

- Press for 120 seconds @ 355 degrees medium pressure. (Time and temp may vary based on your heat press)

-

- Immediately remove and apply heavy even pressure on a smooth flat surface to cool so it will not warp. Make sure all surfaces are clean of grit (all will cause indents on substrate)

-

PRESSING INSTRUCTIONS for Unisub MDF:

- Remove all the clear or blue film from the substrate.

- Remove residue, if any, with a soft damp cloth from unisub MDF.

- Place your MDF substrate onto your transfer and secure with heat tape.

- Press for 50-55 seconds @ 380 degrees medium pressure. (Time and temp may vary based on your heat press

-

- Remove the clear film from both sides of the substrate.

- Place your acrylic substrate onto your transfer and secure (white side against transfer). I use 3m repositional spray so I do not end up with tape indentions on acrylic.

- Press for 120 seconds @ 355 degrees medium pressure. (Time and temp may vary based on your heat press)

- Immediately remove and apply heavy even pressure on a smooth flat surface to cool so it will not warp. Make sure all surfaces are clean of grit (all will cause indents on substrate)

PRESSING INSTRUCTIONS for Unisub Acrylic:

Additional Information

| Options | Gloss Single – No Hardware, Matte Single – No Hardware, Acrylic – No Hardware, Gloss Single – Silver Hardware, Matte Single – Silver Hardware, Gloss 2 Pair Kit With Transfer and Hardware, Matte 2 Pair Kit With Transfer and Hardware, Acrylic 2 Pair Kit With Transfer NO Hardware, Gloss 4 Pair Kit With Transfer and Hardware, Matte 4 Pair Kit With Transfer and Hardware, Acrylic 4 Pair Kit With Transfer NO Hardware |

|---|